How We Build Your Guitar

What sets Kepma apart from other guitar "manufacturers" is our tireless commitment to manufacturing excellence. In our 10 year history, we have developed manufacturing methods and procedures for guitar making that are more precise than 99% of the makers out there. Our processes ensure that your Kepma Elite Series guitar is undeniably the most perfect instrument you've ever had in your hands.

We are one of the world's top builders of guitars. It's all we do, and we've been at it for over 10 years now. Put a Kepma Guitar in your hands and you'll instantly 'feel' our passion and commitment to making the best possible quality guitar.

Watch how Kepma Elite Guitars are made, start to finish…

We truly are a “hands on” manufacturing company… One of our Founders, Jack Peng, is hard at work experimenting with getting more energy out of a guitar top by hand scalloping bracing to the exact shape and thickness.

It all starts with AAA Sitka spruce from Alaska. Two mirrored pieces of quarter sawn solid spruce tops are joined together by this custom designed CNC machine creating the impression of open pages of a book.

Then the matched top blanks are sanded and smoothed to the initial thickness using precision laser-guided sanding equipment.

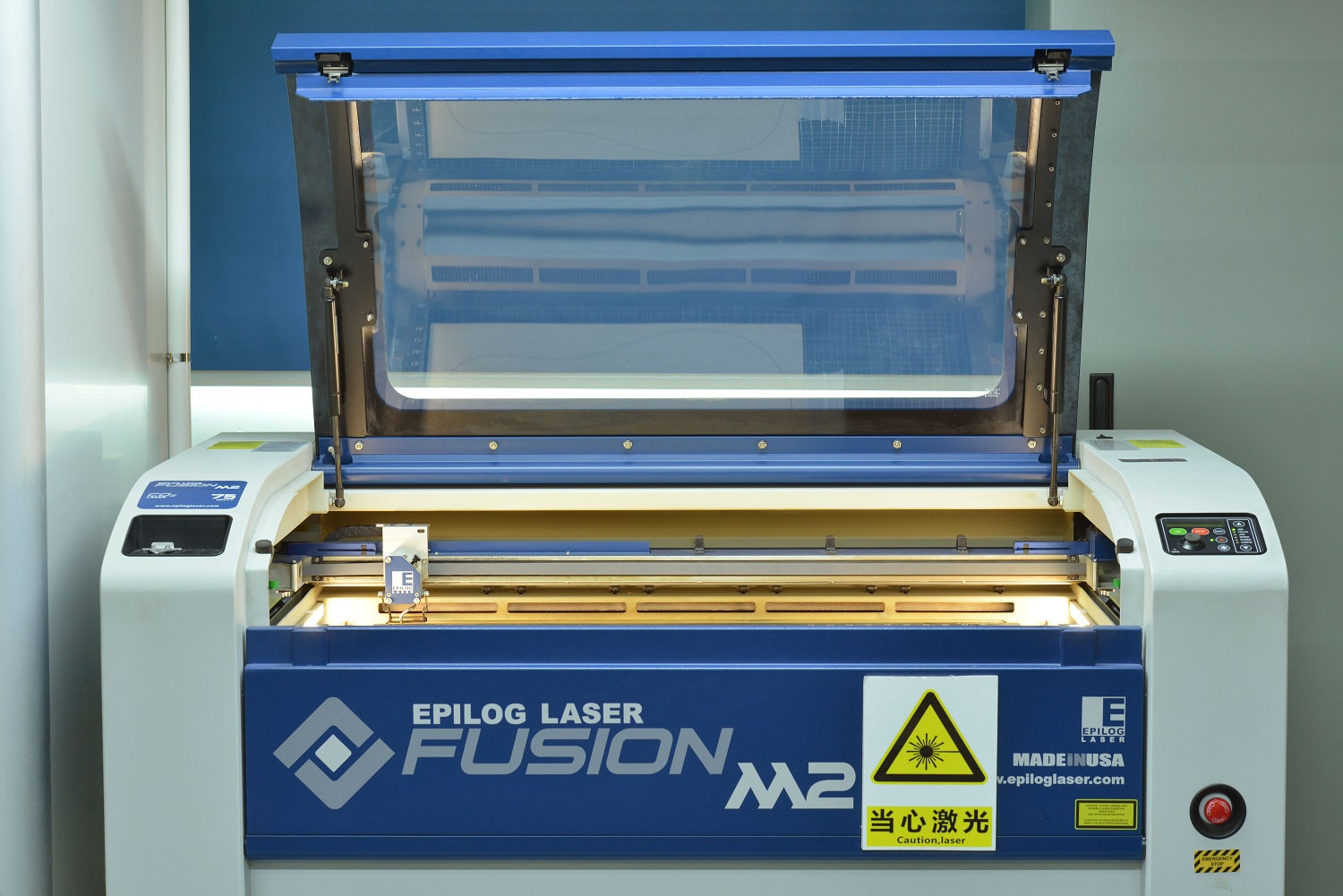

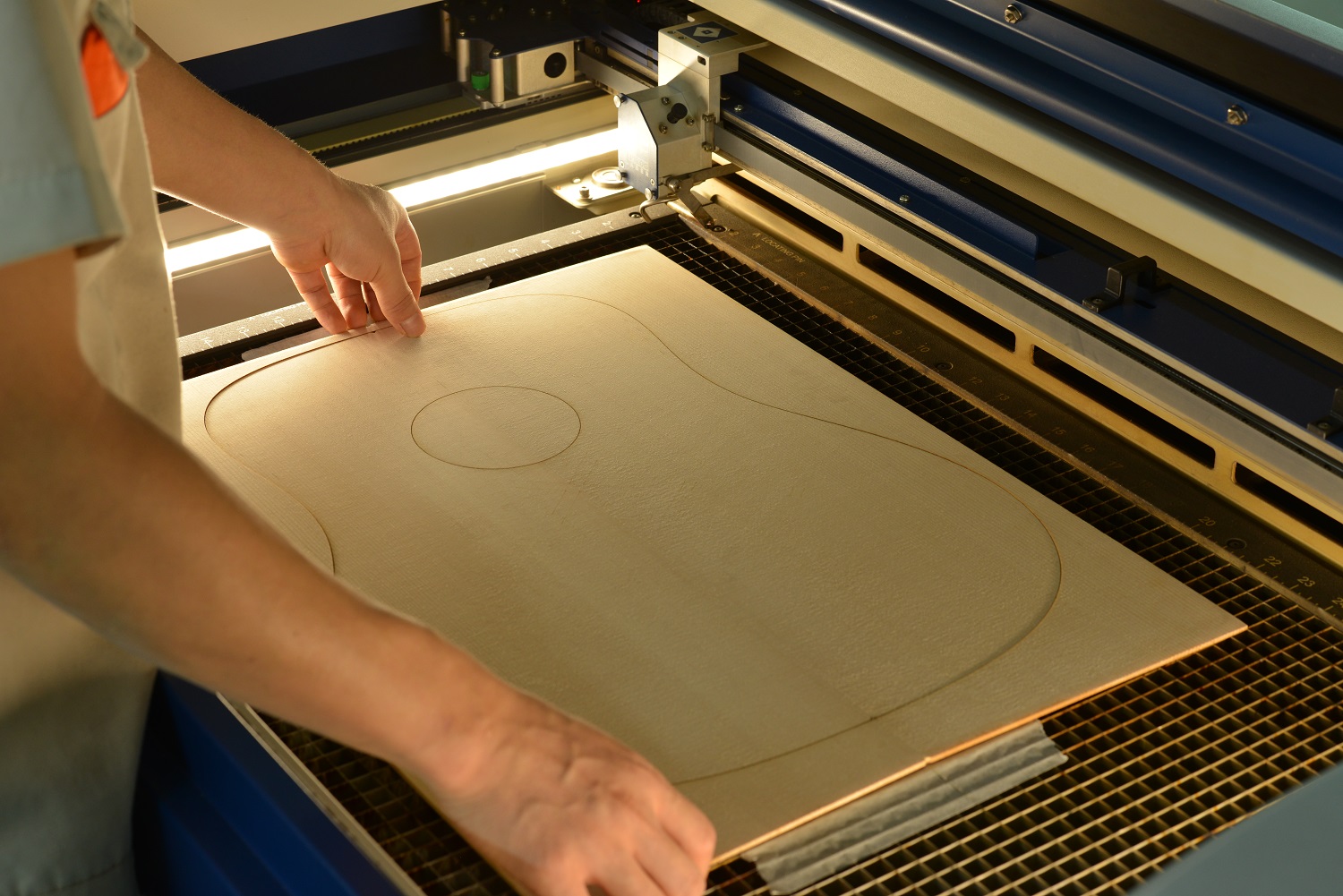

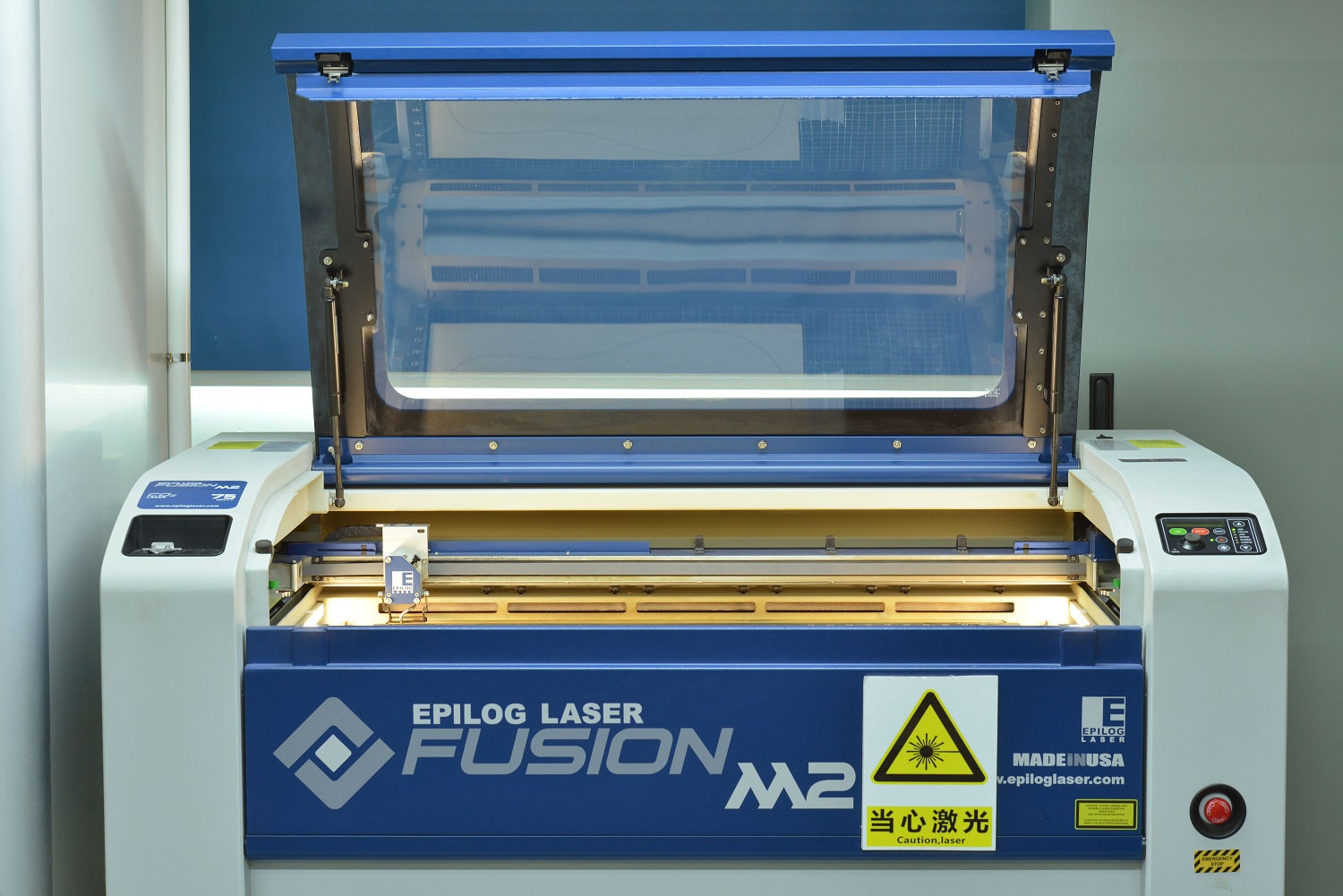

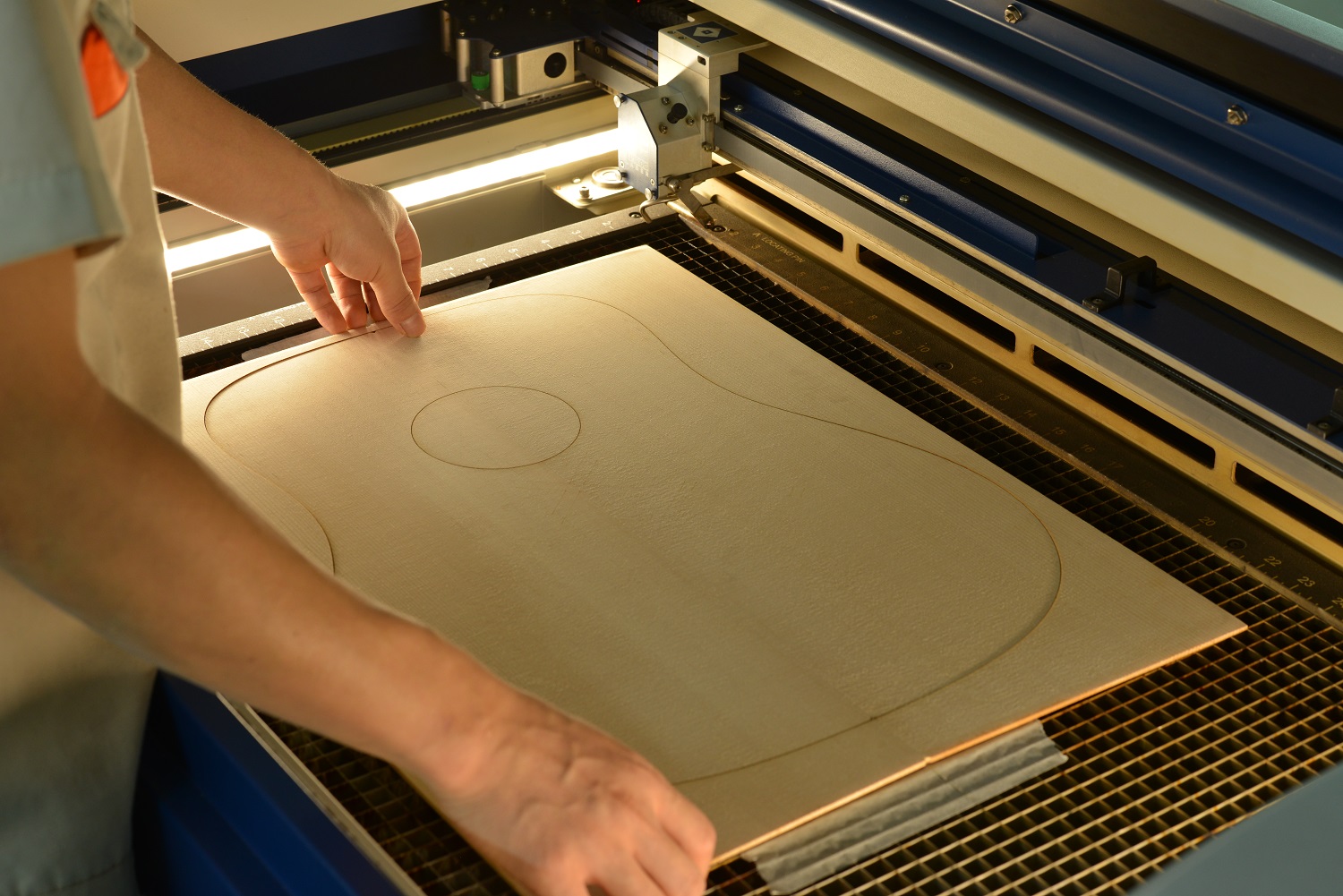

Each top blank is then placed into the laser cutter for precise cutting of the initial top shape.

Once inside the laser top cutter, the shape of the top and sound hole blanks are cut.

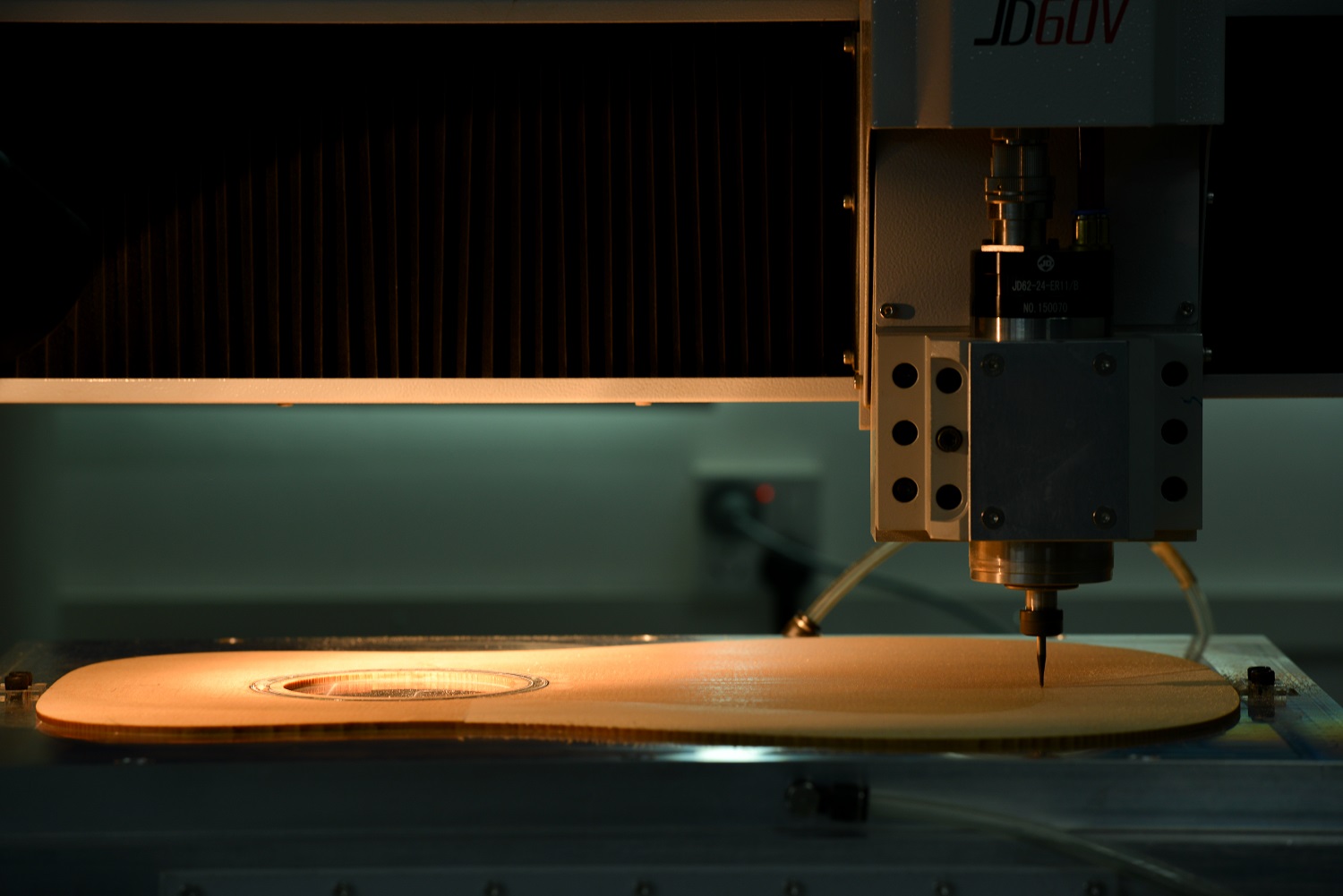

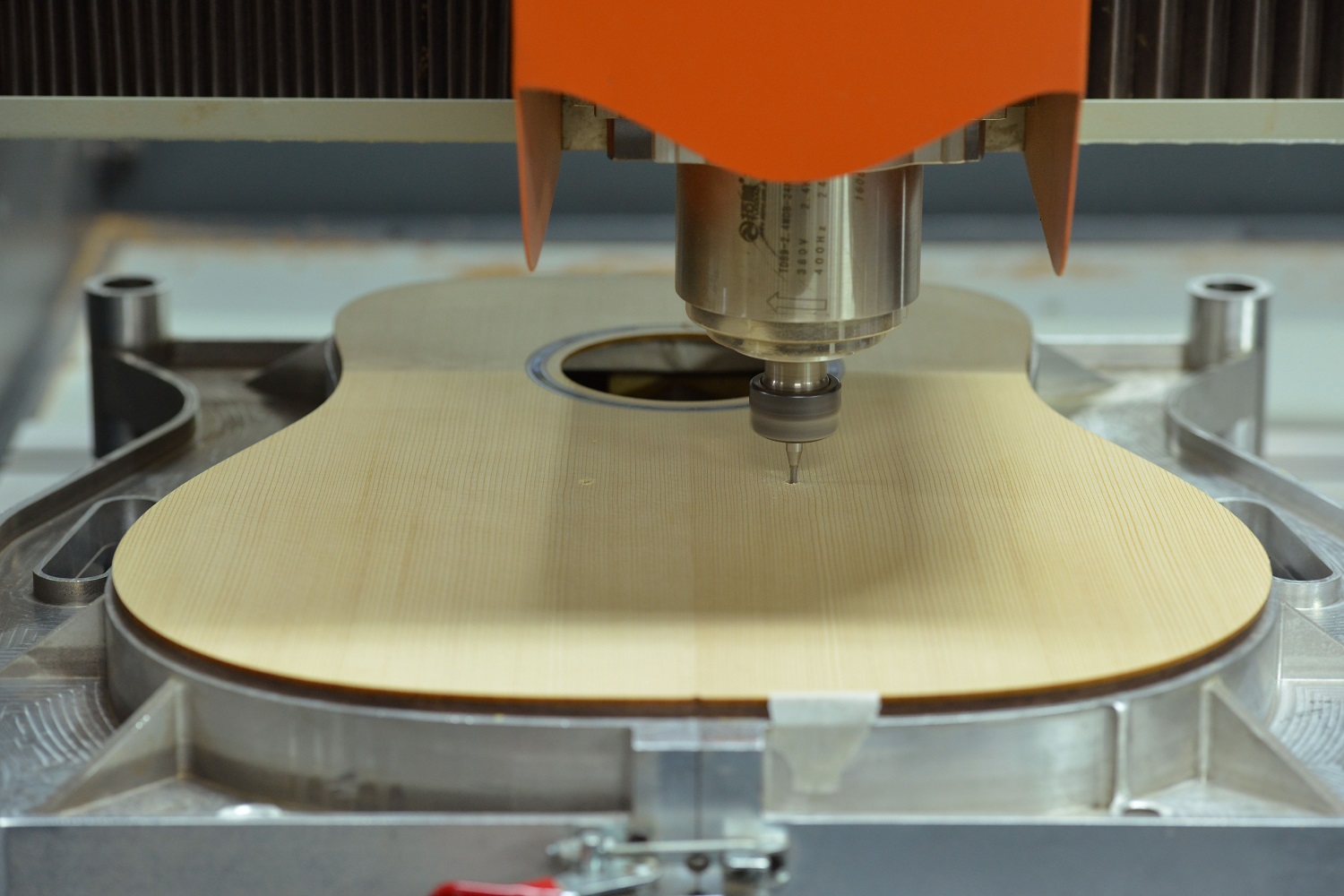

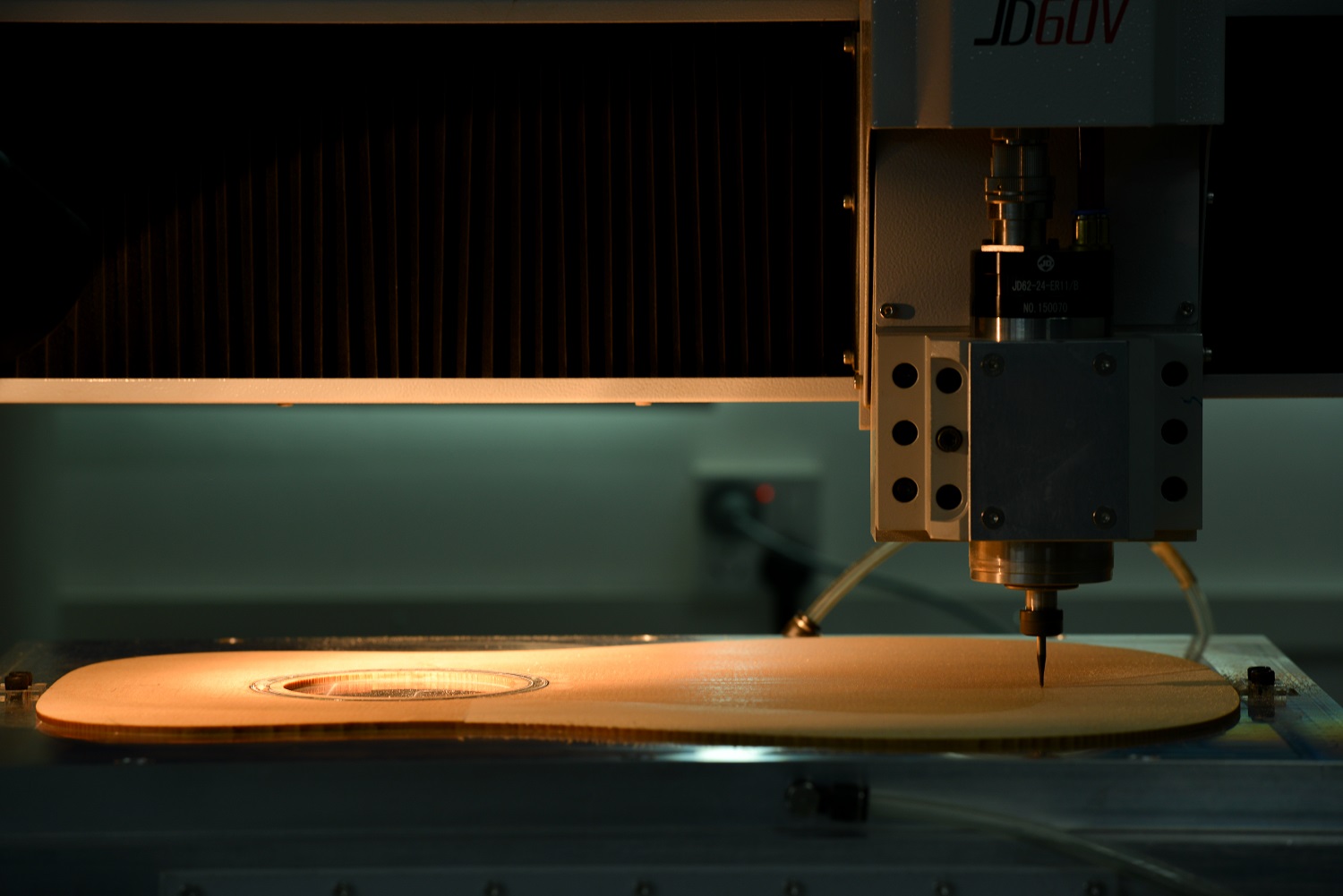

Next up is CNC routing of the soundhole rosette. This precision channel serves as the foundation for the custom abalone inlay around the sound hole, a beautiful adornment to an already precise beginning.

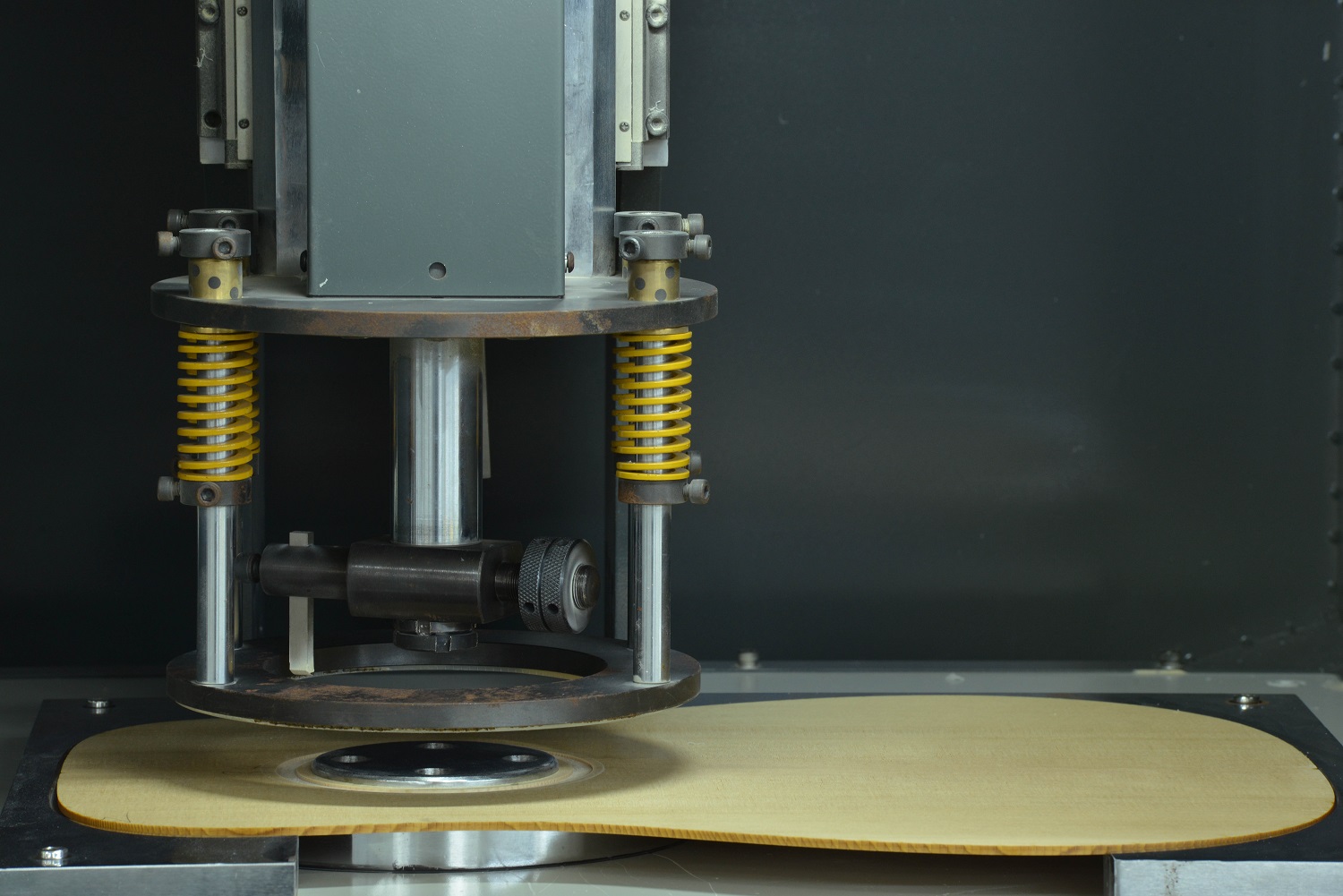

After the top has been cut, it is then placed into another CNC machine to custom taper the top utilizing a highly sophisticated topographic “map” to provide the proper tonal qualities.

After cutting the rosette channel, the top is then tapered matching a precise topographic “map” that provides strength, stability and most importantly the proper frequency response “balance” needed for precision high-quality instruments.

After tapering, each top is hand “tap” tuned to measure the overall balance and frequency response of the top. If the frequency profile is not precisely “matched” to the desired profile, then the top is put back into the tapering CNC for additional refinement until the response perfectly matches the desired response profile of the instrument.

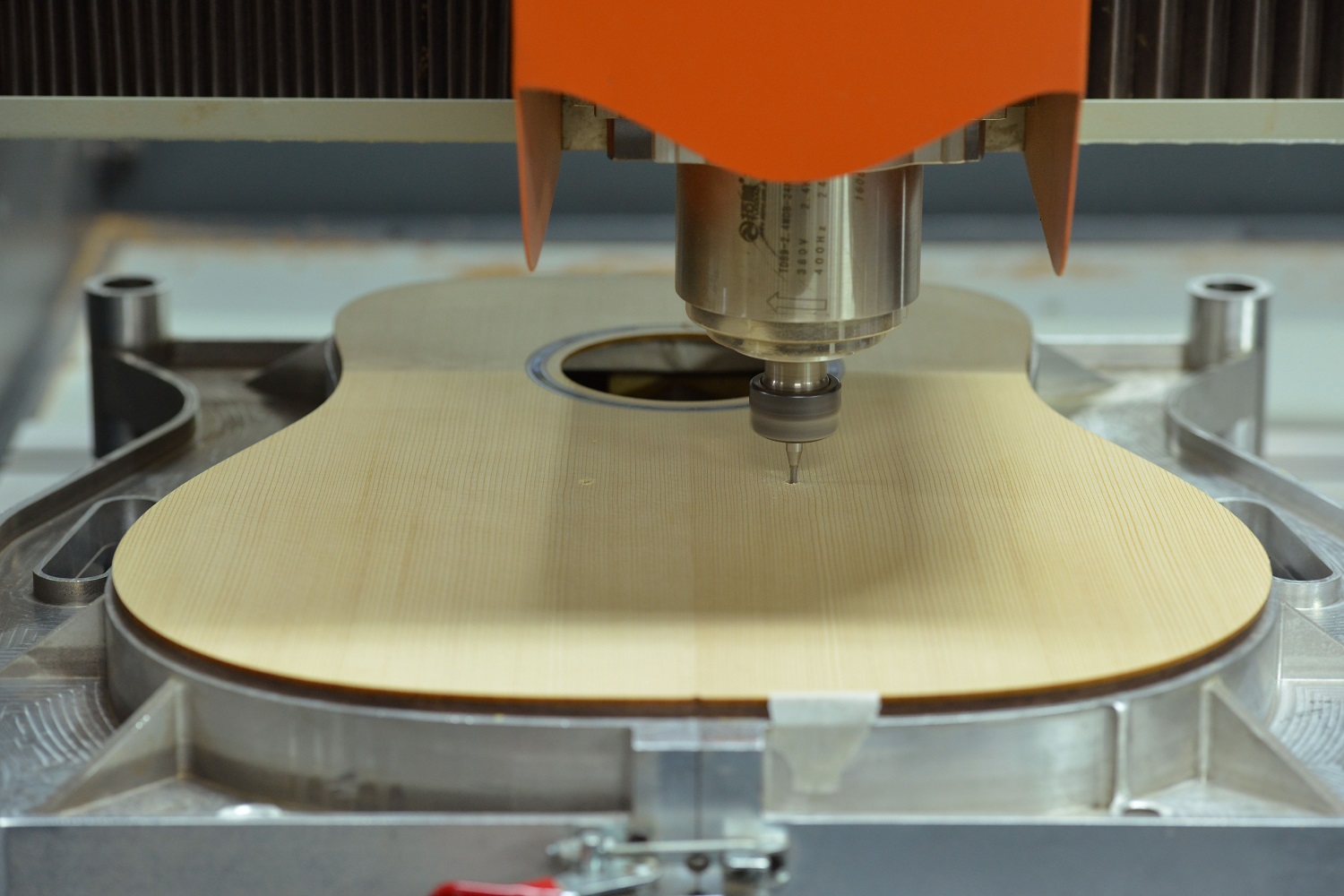

Once tuned to perfection, the next step is to cut the bridge placement and string hole positions. This is also done with precision CNC equipment to ensure that the bridge is placed in precisely the correct location for maximum transference of the string vibration to the top.

At Kepma, nearly EVERY part of the instrument building process has been precisely studied and replicated with precision equipment to ensure the best possible build quality — even down to the precise application of the bracing glue, both in placement and amount used. Nothing has been overlooked in the process of building some of the world’s finest guitars.

Top bracing is one of the most critical aspects of acoustic guitar building. When done properly, the bracing provides the highest level of stability to the top during performance without interfering with the sonic performance of the instrument — in many cases the bracing pattern dictates the degree of warmth, sustain and overall tone quality. Kepma Elite bracing is precision crafted from solid AAA Sitka spruce using precision CNC machines.

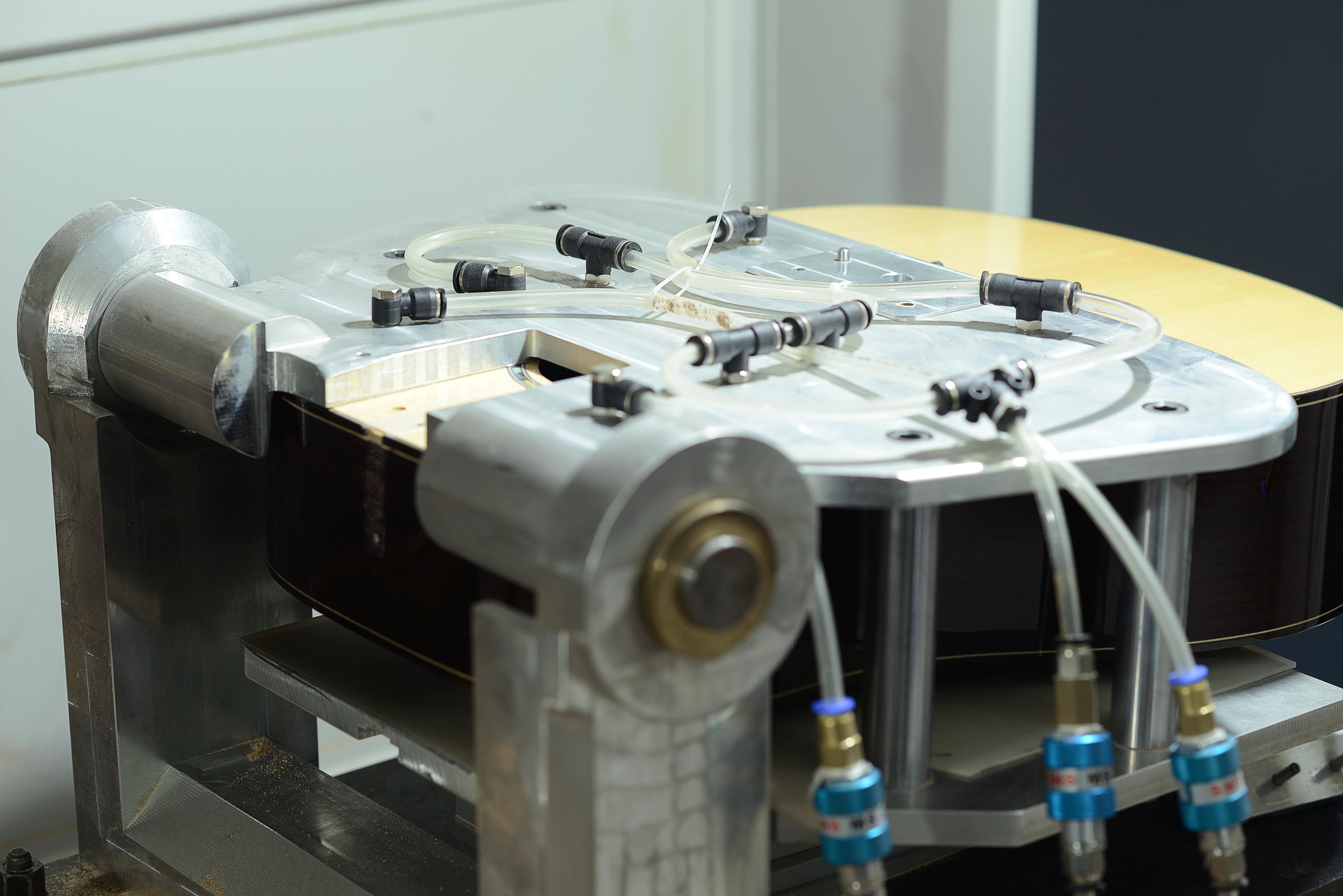

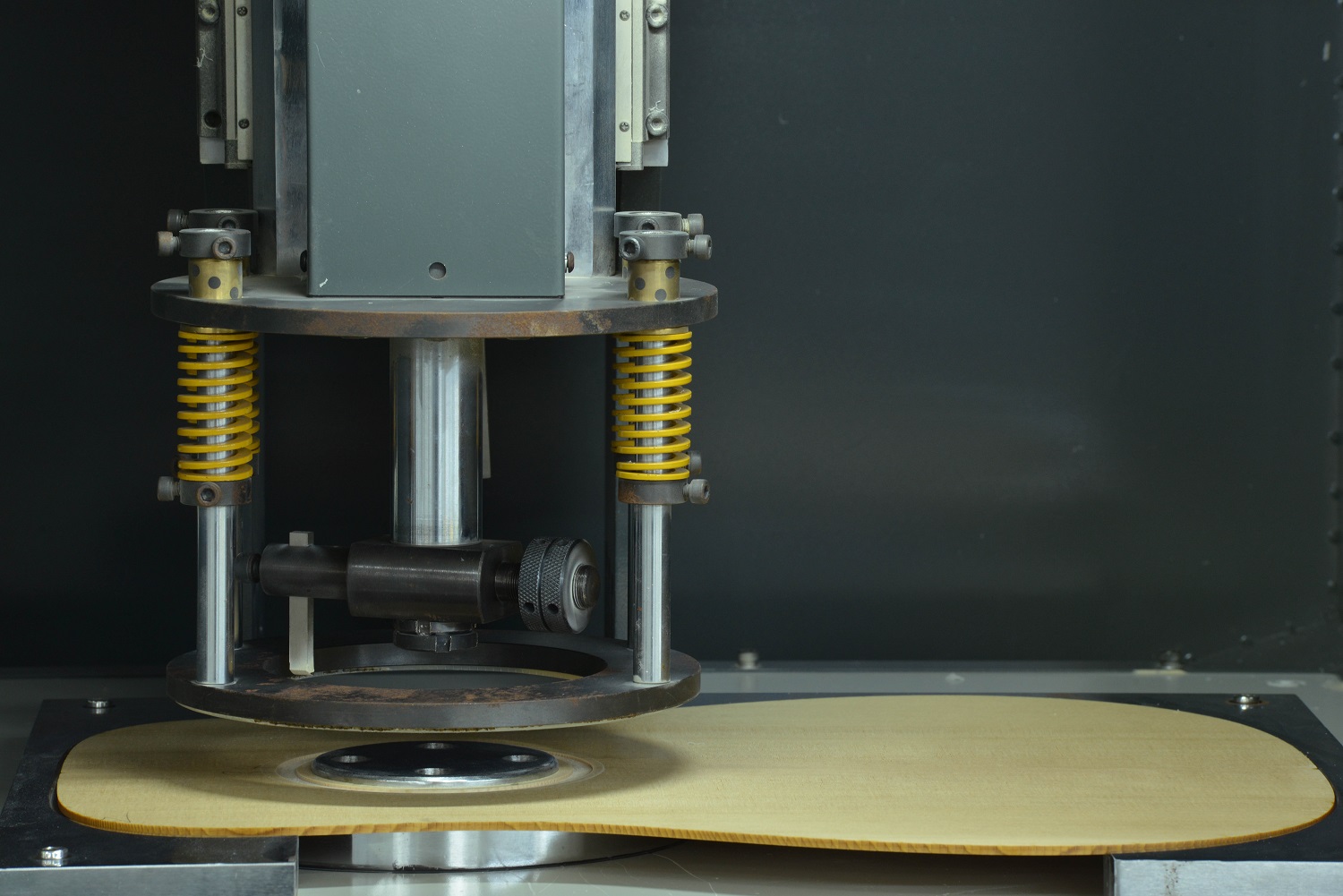

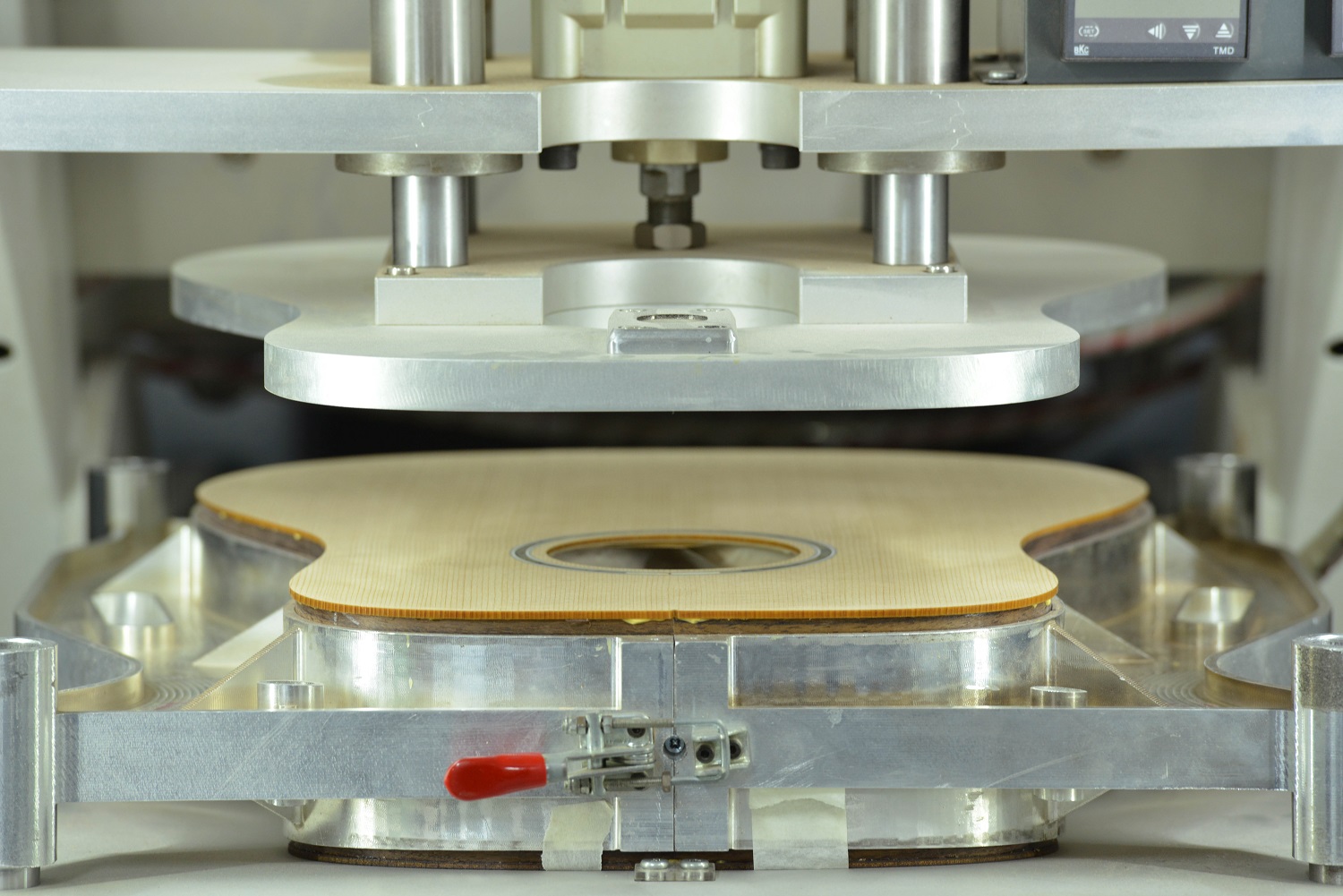

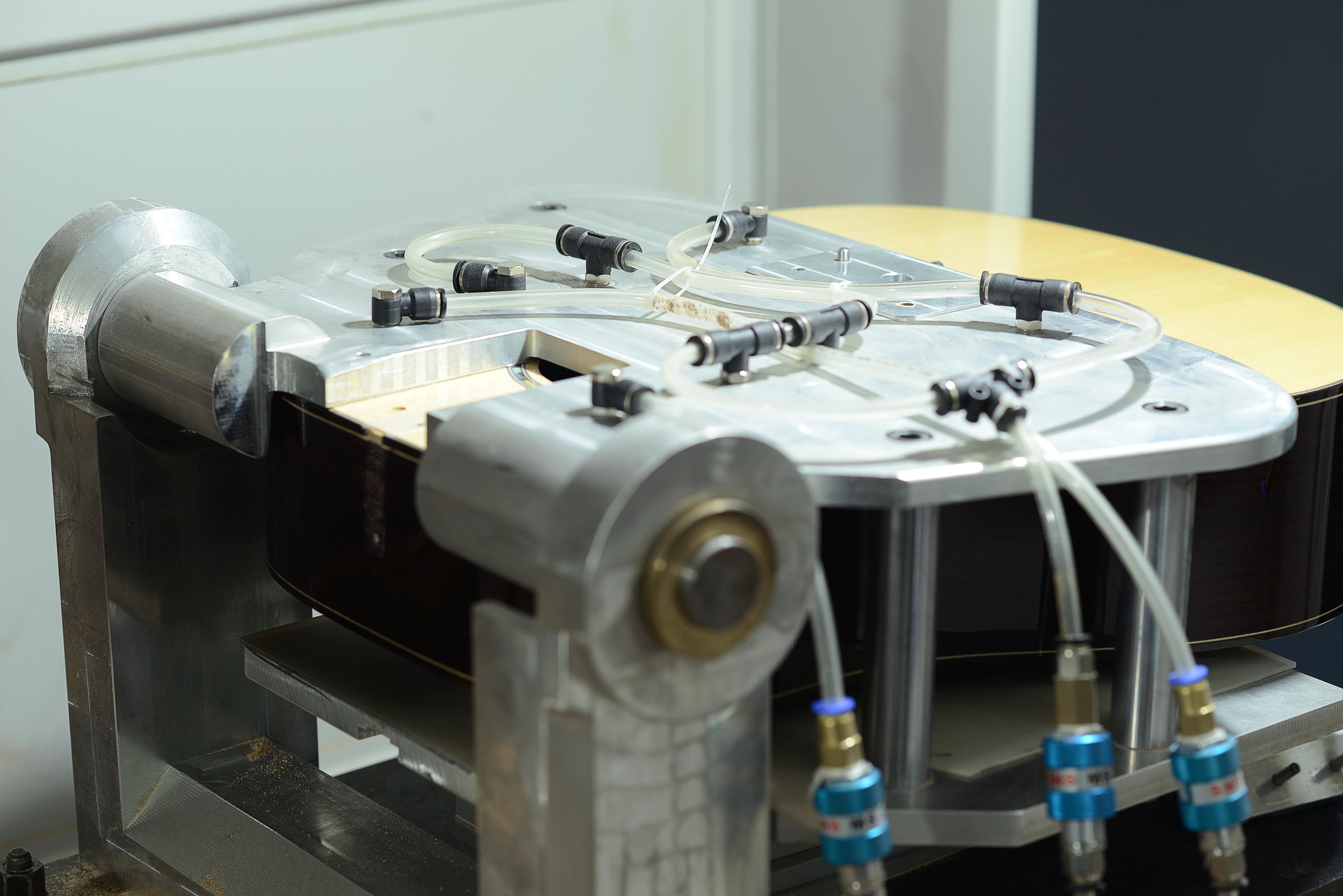

Again, bracing is one of the most critical components of instrument tonal performance. At Kepma Elite, not only is just the proper amount of glue used to adhere the bracing, but each top is placed in a vacuum pressure “curing” station that completely eliminates all traces of air and environment so that the bracing system truly becomes “one” with the top, producing a level of sonic purity and “loudness” most manufacturers simply cannot achieve.

A 5-Axis precision CNC machine is used to cut the side pieces prior to shaping. The precise nature of the cut ensures the proper fitting of the perfling for back & top placement.

Kepma Elite utilizes multiple CNC machines and cutting heads for each part of the process. The use of CNC ensures that each guitar is identical in tolerances and sounds the way it’s meant to sound — Perfect. Every time.

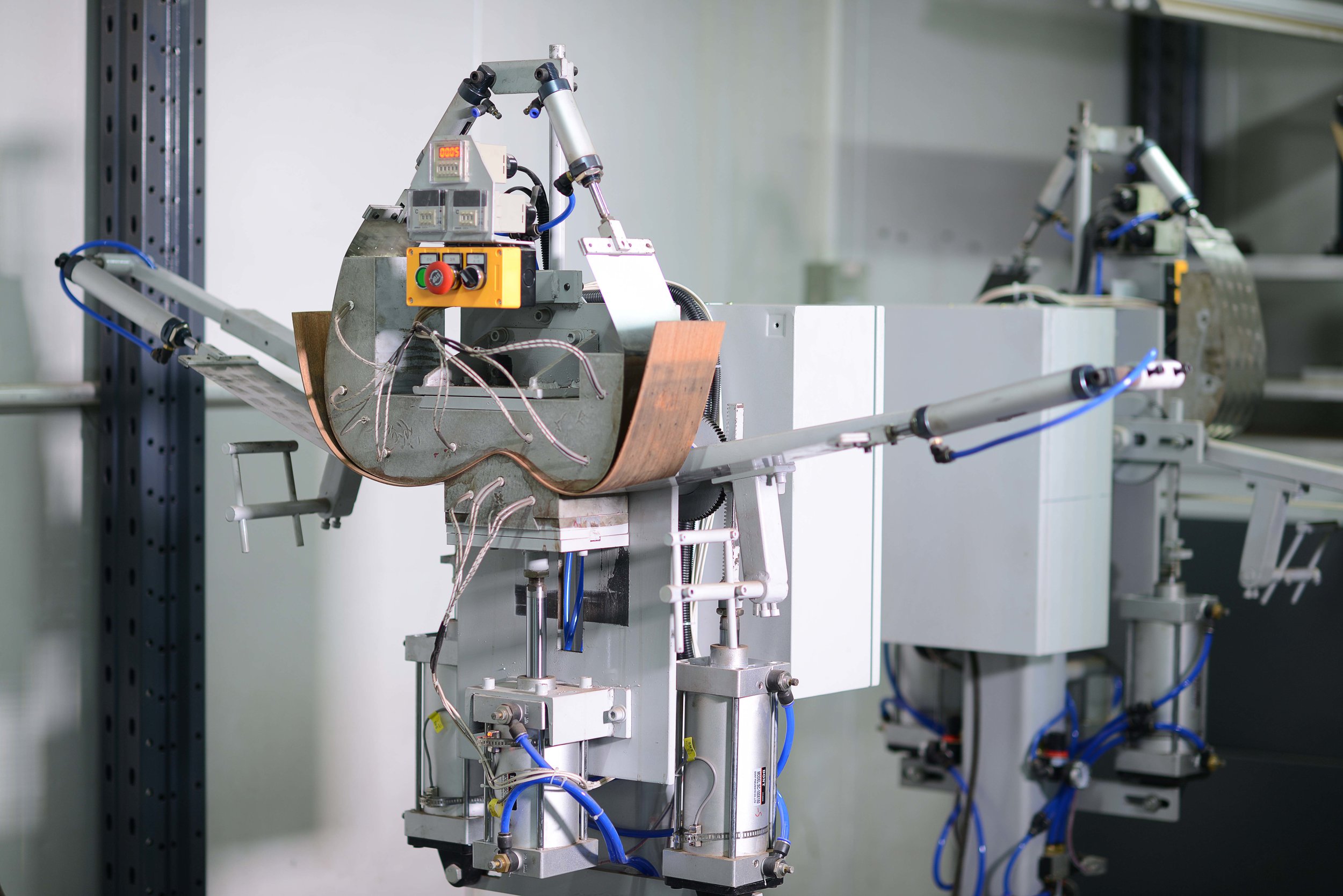

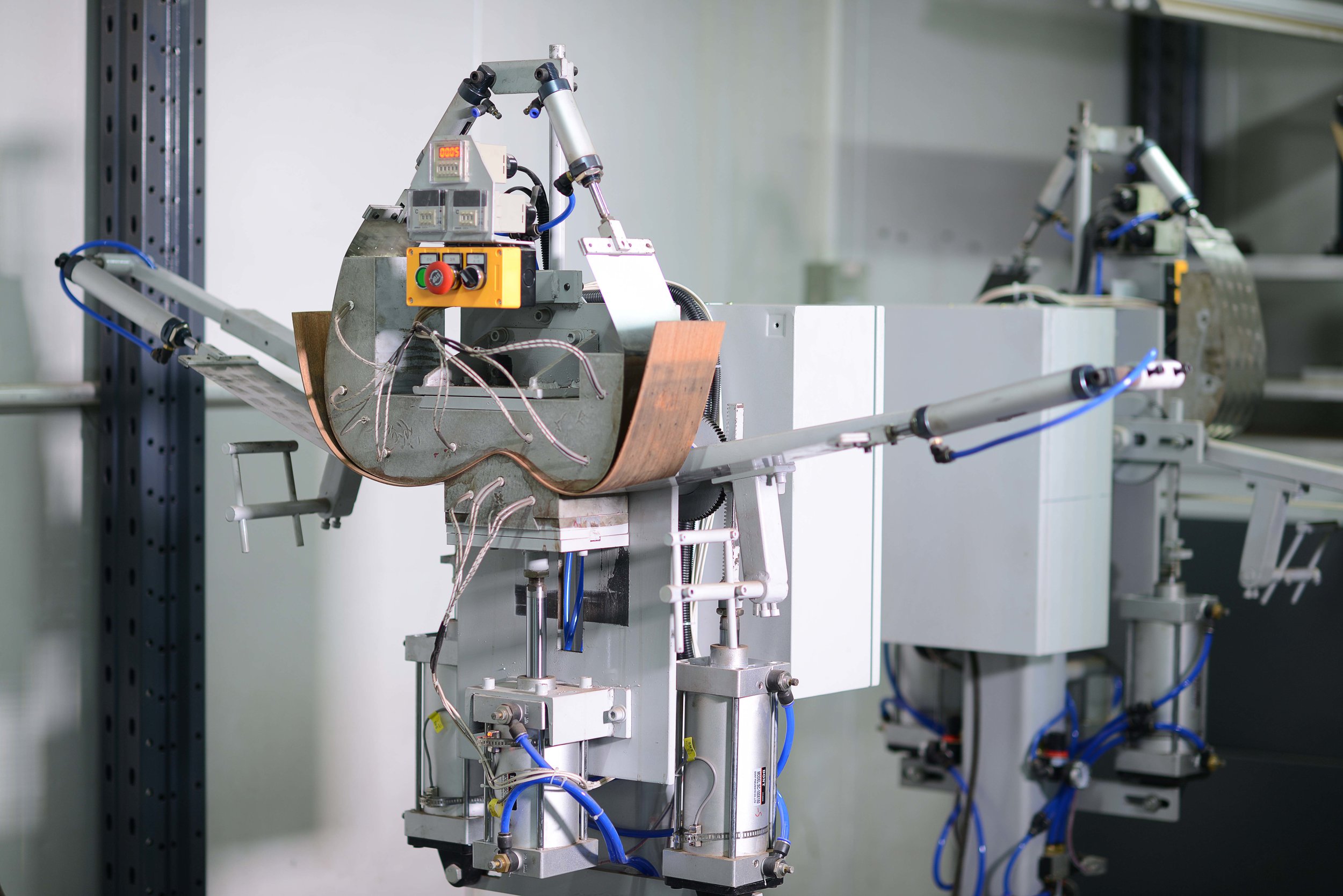

Kepma Elite employs a new generation of “side shaping” equipment that maintains the structural integrity of the side materials better than the traditional “steam bending” techniques employed by other makers. Without “weakening” the woods used with steam, the guitar is better able to project with more confidence and volume.

Each Kepma Elite guitar has its own set of side curve “shape” guides that ensures precision shaping of the instrument body time after time.

Purfling provides the “bed” for the resting and adherence of the back and top of the guitar. It’s purpose is to provide a solid foundation for the attachment of the components while not interfering with the sonic contributions of each. Therefore, the purfling must be scientifically precision-cut to allow for the perfect “bend” while not muffling the sound of the instrument. Kepma Elite purfling is also precision cut from sitka spruce, and a computer controlled gluing station ensures the perfect amount of glue is applied.

Multiple clamp points ensure that the perfling is 100% attached to the sides of the guitar which provides better transference of vibration throughout the instrument.

Once the purfling glue has cured completely, the instrument is placed in a CNC machine for precision routing of the purfling so the top and back will fit precisely in the body.

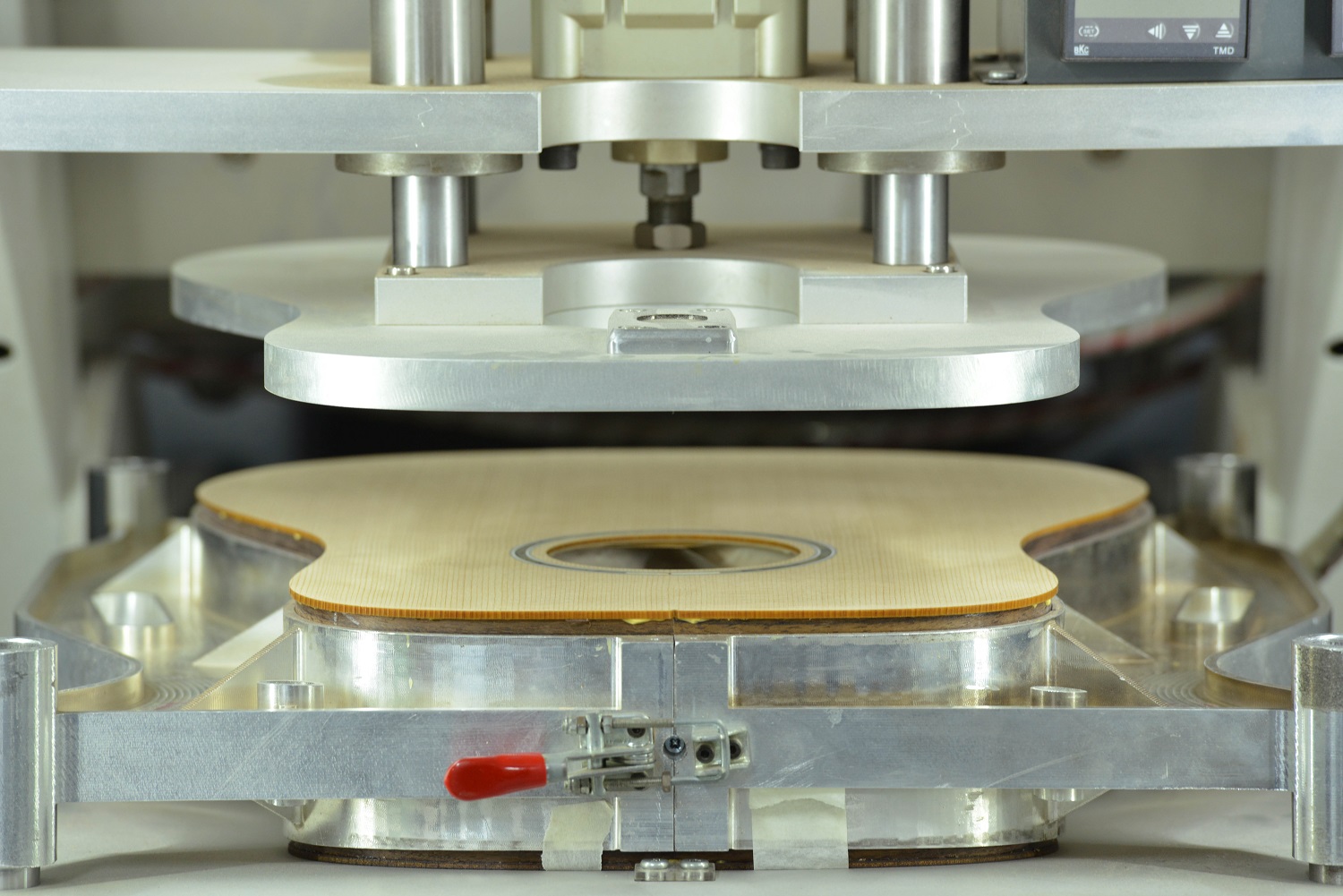

Once everything is precise, it’s time to join the top, back and sides to complete the guitar body shape. This process is also pressure controlled and precise down to 1/1000” tolerance to ensure proper fit and optimum performance of the instrument.

Consistent pressure across all top coordinates ensures the perfect fit between the resonant top and the adjoining perfling on the sidewalls.

In this station, guitar neck shaping is fine-tuned with CNC “trimmers” prior to hand sanding and finishing.

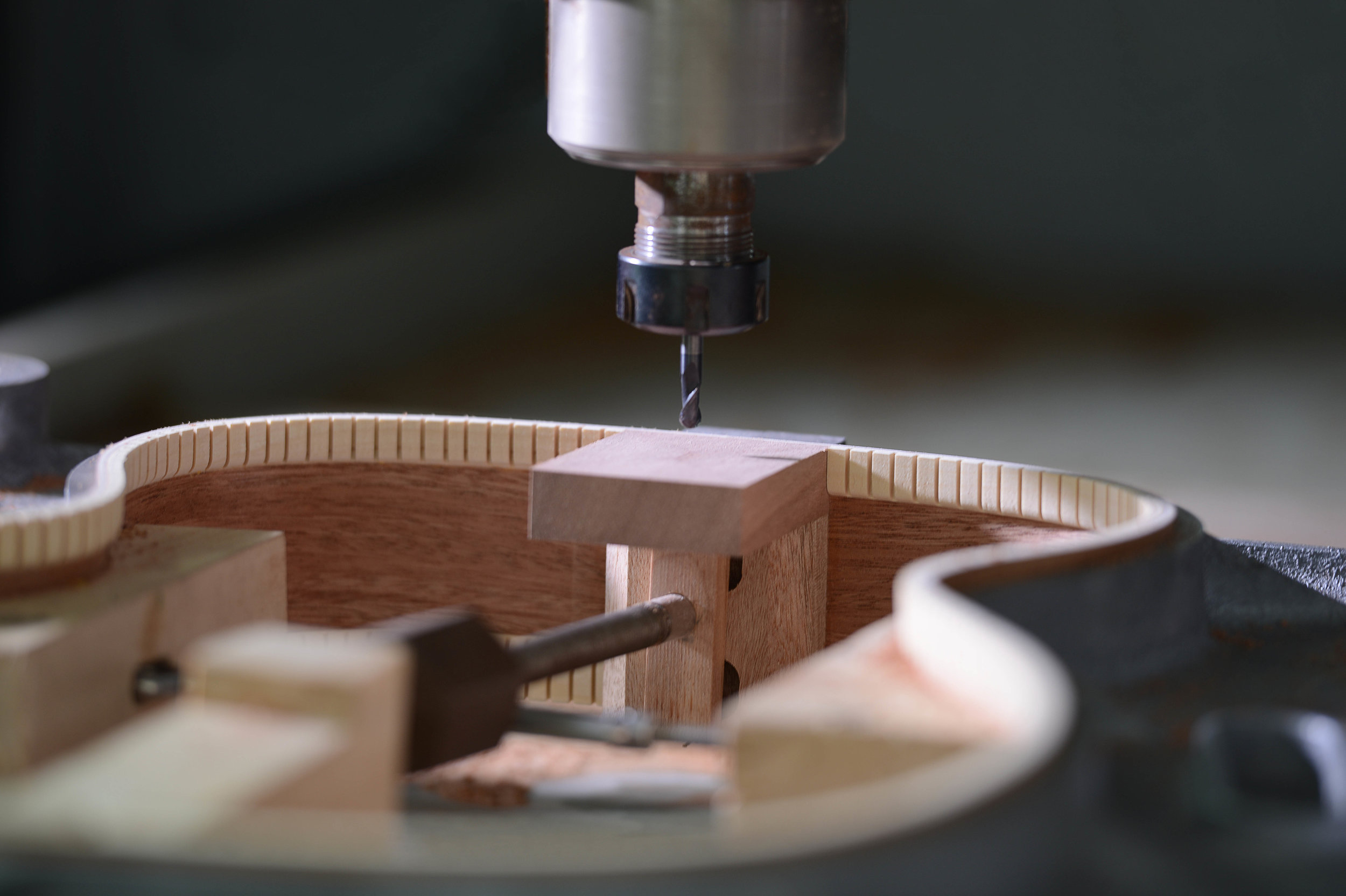

Here the holes are precisely placed and drilled for the acceptance of the tuning machines. Another step beyond this one ensures proper fit with zero energy loss due to gaps between the tuners and the headstock.

Every Kepma Elite neck has 3 individual stabilizers: A two-way truss rod and 2 carbon fiber rods on either side of the truss rod. These extra stabilizers allow us to create a thinner neck profile that is easier to play without fatiguing the player's hands.

CNC routers are utilized here to finalize the holes for the tuning machines. Each one is carefully inspected for tolerance and fit after completing this station.

Kepma Elite bridges are precision cut from African Ebony or Rosewood. Special care is taken during this process as the bridge is one of the most crucial “joints” in guitar construction and must be precise. Otherwise there is mechanical energy (and thus, sound character) lost in the transference of the string vibration to the top.

While the inlay channels and pieces are precision cut by machines, each Kepma Elite inlay is placed by hand ensuring the artistic eye and aesthetic beauty of a hand-crafted inlay.

Each piece of inlay shell is hand placed by inlay artists who possess a keen eye for balance and just the right brilliance to create a true work of art.

Everything about a Kepma Elite Guitar is precise, all the way down to the finest detail of cutting the visual side markers on a fretboard to be perfectly round, every time.

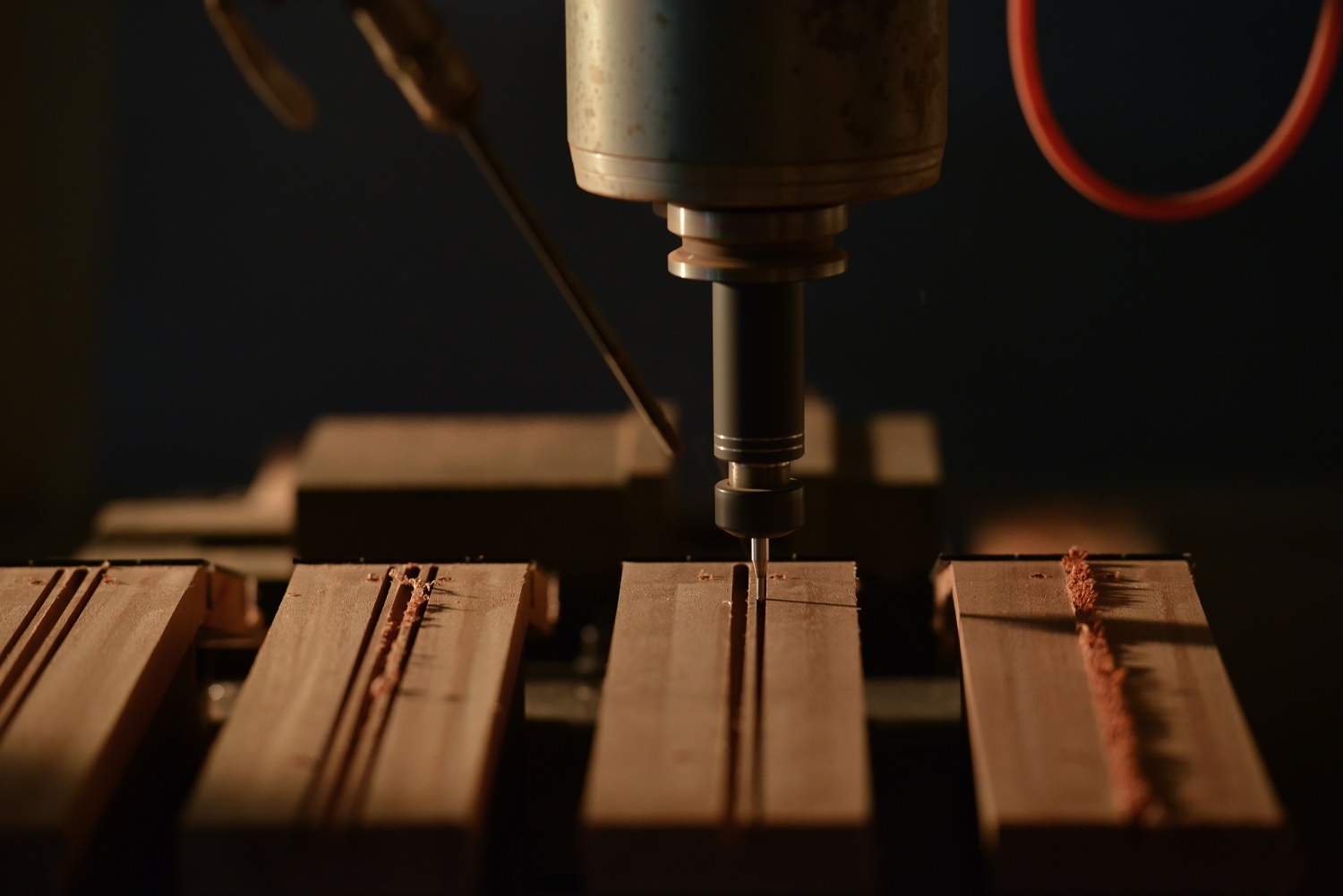

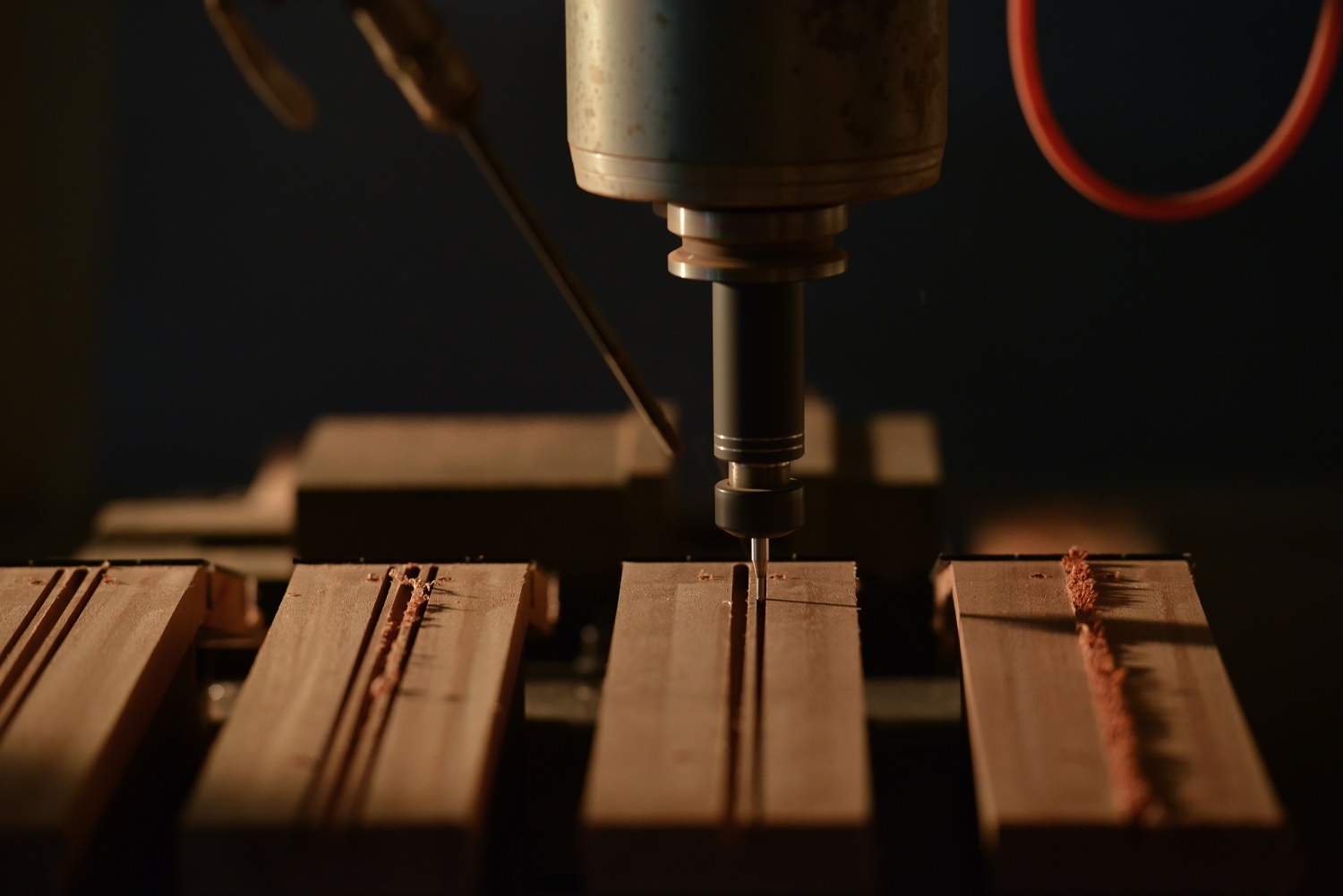

Making the perfect guitar means that everything must be precise and “fit” together with perfect tolerances. Cutting the fret wire slots at precise angles and depths means the frets will be perfectly seated with no gaps — a solidly seated fret aids in the transference of energy to the body, but also helps the instrument keep perfect intonation — Every time.

Spray booths at Kepma Elite are fully automated with ABB robotics to provide the safest possible environment for our craftsmen while applying precise amounts of the proper finish.

The neck block is precisionly placed, glued and drilled ensuring the proper transference of vibration throughout the instrument.

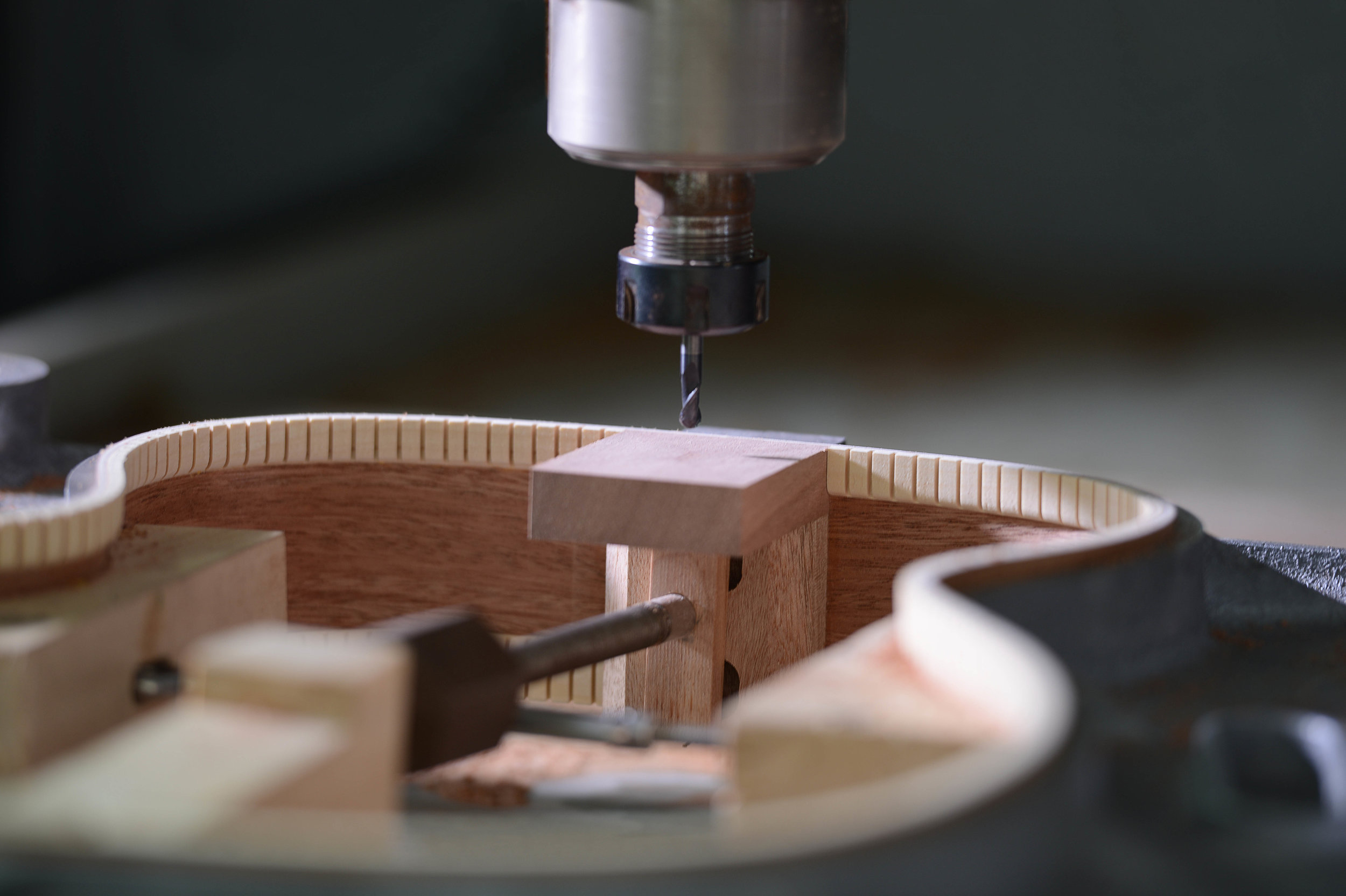

The most critical aspect to a guitars playability is joining the body and neck. Kepma uses highly accurate CNC machines to accomplish this feat flawlessly.

Each body is placed in a precision press neck joint cutting machine that uses vacuum pressure to hold the body in place with absolutely no movement during the process.

Cutting the channel for the neck joint requires extreme precision — the neck joint is perhaps the most critical joint in the guitar and where many manufacturers fall short. Kepma Elite neck joints are so precise that there is virtually zero tolerance variation resulting in nearly 100% tonal transference and one of the strongest joints in the industry.

Again, CNC machines cut the perfect neck joint on all Kepma Elite Guitars.

Prior to hand assembly, each neck and body joint are inspected for continuity to ensure precise neck angle and placement. The bolted neck process provides strength and consistency. It even allows for neck replacement in the case of an unfortunate mishap.

After coming out the production line, guitars are staged in preparation for the “vibration” room where each instrument is subjected to 300 hours of “settling in” prior to final packaging and shipment.

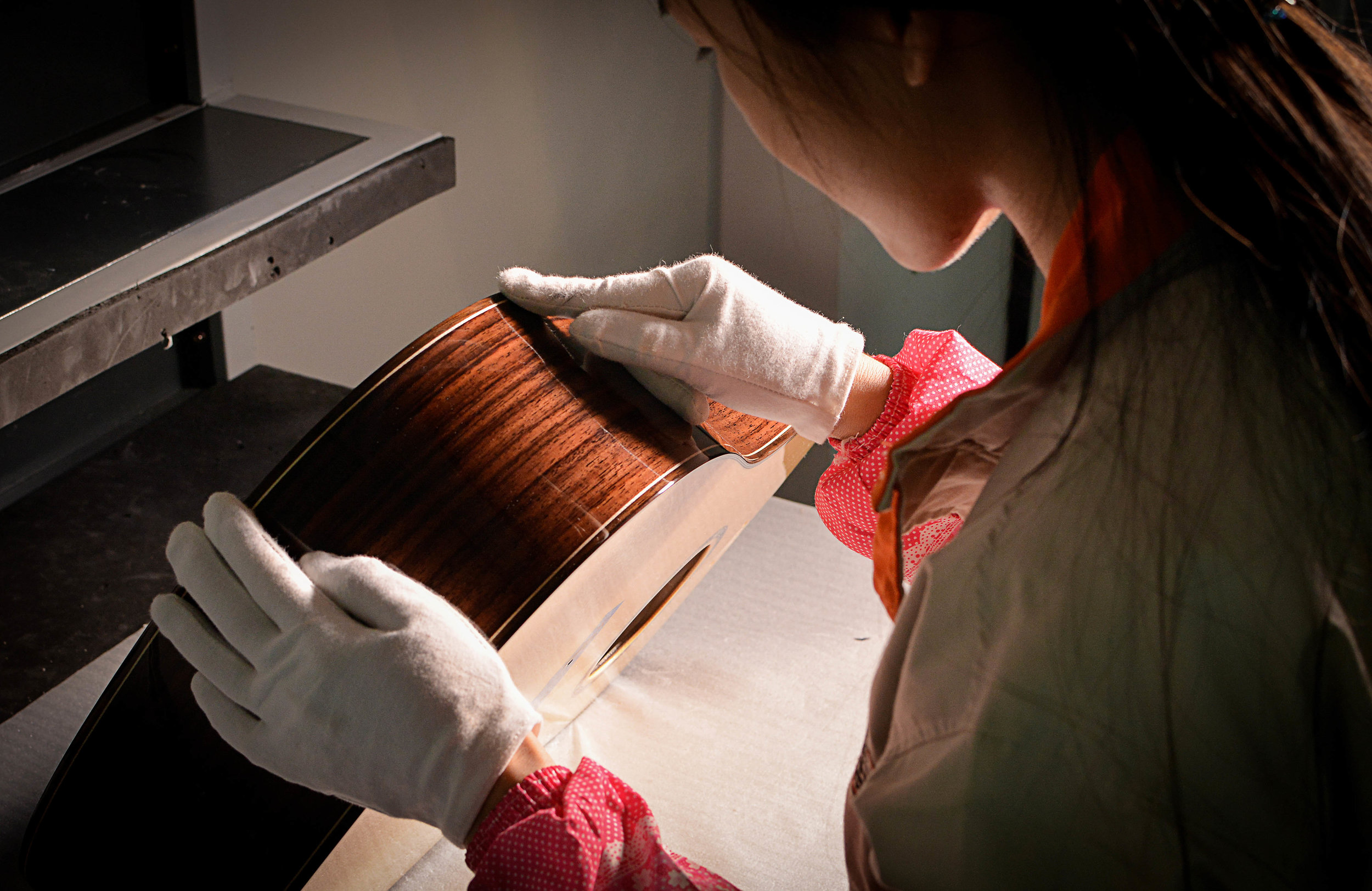

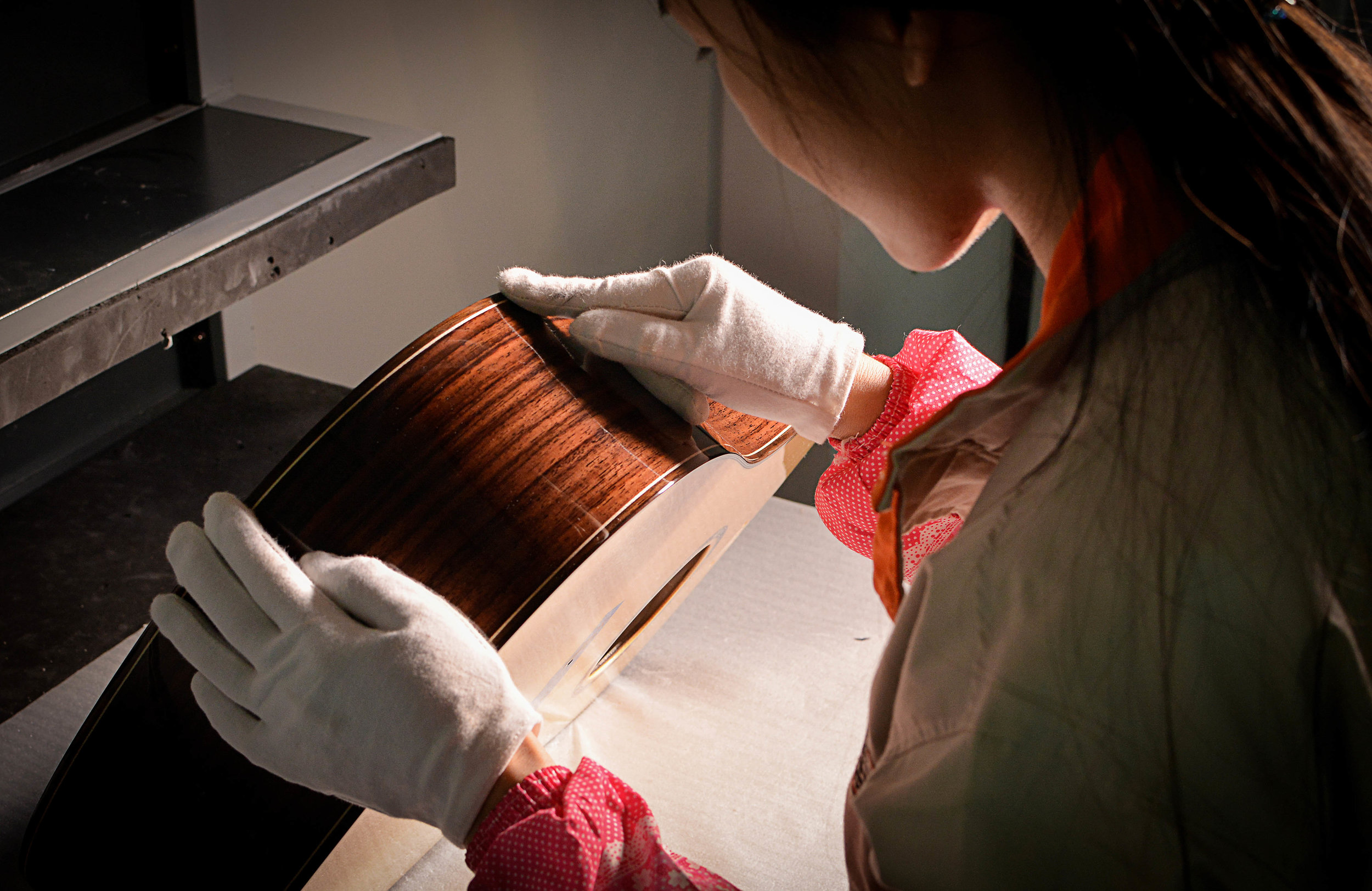

After sanding, finishing and buffing, each guitar is hand / eye inspected to ensure flawless performance.

After the final inspection stage, each Kepma Elite Guitar is packed in it’s case or padded bag with its accessories. It’s then ensured to stay in its factory condition backed by the Kepma Lifetime Warranty.